two.2 Normally cleaning validation could be relevant for important cleaning such as cleaning involving producing of one merchandise and another, of surfaces that arrive into contact with merchandise, drug goods and API.

It's an experienced program platform that scales extractables facts for Sartorius goods and assemblies and predicts the full number of extractables determined by your course of action:

The Selection of solvent for any swab, if in addition to drinking water shall be dependant on the solubility of the Lively ingredient.

Tools sterilization processes is probably not adequate to accomplish substantial inactivation or removal of pyrogens.

I want to join newsletters from Sartorius (Sartorius AG and its affiliated corporations) based of my personalized pursuits.

Cleaning validation troubles in sterile producing consist of validating cleaning treatments for elaborate devices, ensuring the removal of all sorts of contaminants, and retaining consistency in cleaning procedures.

Right here we stated a list of prevalent job interview questions and solutions on pharmaceutical output (Primarily reliable dosage kind): Q. What is pharmaceutical Pill?

Then validation in the worst situation of the previous equipment chain can even justify the cleaning validation in the afterwards, even the worst-case product or service of each the chains would not match.

You’ll still ought to validate your cleaning methods when applying dedicated devices for particular processes.

Sampling is among The main features on the cleaning validation approach. It enables businesses & cleaning pros to guarantee that a surface area or piece of kit adheres more info to cleanliness & hygiene benchmarks.

Learn about the treatment for cleaning validation and cleaning validation protocol and experiences as per WHO. Method of sampling, Analytical methods and limits of Restoration of swabs. worst situation review in cleaning validation.

I would cleaning validation guidance for industry like to enroll in newsletters from Sartorius (Sartorius AG and its affiliated firms) centered of my personal pursuits.

Depending on the analysis, compute the amount of residue current in Each and every rinse/swab, and on the basis of rinse/swab end result and evaluate possible contamination in the next product, estimate the quantity of residue existing in each products involved.

The assertion could be justified just as if worst-situation items in the worst equipment chain (acquiring greatest surface region) are validated successfully,

Elin Nordegren Then & Now!

Elin Nordegren Then & Now! Nancy McKeon Then & Now!

Nancy McKeon Then & Now! Raquel Welch Then & Now!

Raquel Welch Then & Now! Tonya Harding Then & Now!

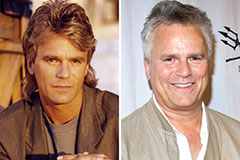

Tonya Harding Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!